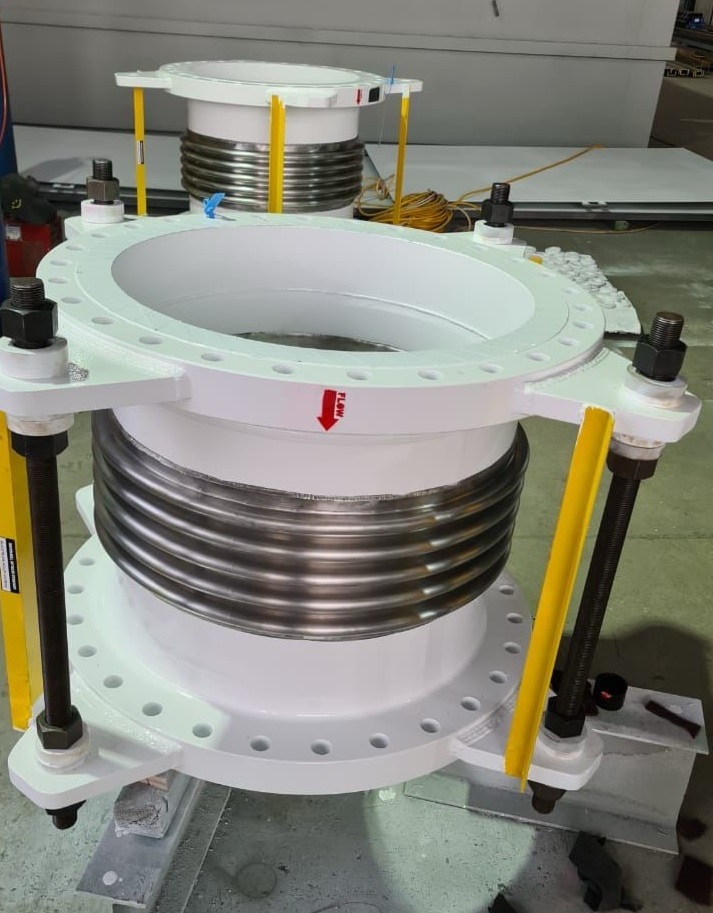

Metal Expansion Joints

Engineered Expansion Joints for Demanding Industrial Applications

Precision-Designed Metal Bellows for Thermal and Mechanical Compensation

At VT Top Engineering Pte. Ltd., we specialize in the design and manufacture of metallic expansion joints engineered to accommodate a wide range of operational stresses in industrial piping systems. Our expansion joints are critical components in systems subject to:

- Thermal expansion and contraction

- Axial, lateral, and angular movement

- Vibration isolation

- Pressure thrust containment

Manufactured using SA240 Gr. 304/316/321 stainless steel as standard—with higher-grade alloys such as Inconel, Incoloy, and Hastelloy available upon request—our bellows are designed to perform under high-pressure (up to 15,000 KPa) and high-temperature (up to 1100°C) conditions.

All expansion joints are factory-tested to 1.5× their rated pressure, ensuring structural integrity and operational safety. Each unit is optimized based on fluid media, flow velocity, and system dynamics.

Backed by advanced fabrication techniques and stringent quality control, our joints provide consistent mechanical performance and system longevity.

Broad Range of Configurations for System-Specific Challenges

Expansion Joint Types and Functional Capabilities

We offer an extensive portfolio of metallic expansion joints tailored to specific movement and load conditions. Each design is governed by precise mechanical parameters, including spring rates, deflection limits, and allowable pressure thrust.

Single Expansion Joints (SEJ)

- Accommodate pure axial movement

- Suitable for short, anchored runs with guides

- Require thrust-resistant anchors

Universal Expansion Joints (UEJ)

- Designed for lateral movement in multiple planes

- Incorporate dual bellows and center pipe

- Require anchoring to manage pressure thrust unless tied

Tied Expansion Joints (TEJ / TUEJ)

- Equipped with tie rods to eliminate pressure thrust

- Ideal for absorbing lateral deflection while isolating anchors

- Used in systems where axial motion is restricted

Hinged and Gimbal Expansion Joints (HEJ, GEJ, DHEJ, DGEJ)

- Permit angular rotation in one or two planes

- Do not allow axial movement

- Low reaction loads, ideal for large structural deflections in long pipe runs

Externally Pressurized Joints (XJ)

- Specifically for large axial movements in long, guided pipelines

- Bellows are pressurized externally to prevent squirm instability

- Effective in confined spaces like tunnels and shafts

All designs are validated per applicable international codes (e.g., EJMA, ASME) and customized based on fluid dynamics, pipeline routing, and environmental factors.

We provide movement calculations, anchoring force estimates, and guide spacing recommendations with every project design.

Engineering Support, Installation Integrity, and Lifecycle Reliability>

Comprehensive Technical Support and Installation Guidance

The performance of an expansion joint is not solely defined by its materials or design—but by its proper handling, installation, and system integration.

To ensure long-term reliability, our products are accompanied by:

- Detailed handling guidelines to prevent convolution damage and corrosion

- Installation best practices including correct guide spacing, anchor positioning, and insulation selection

- Flow alignment protocols to maintain performance efficiency

We also recommend:

- Internal liners for high-velocity or abrasive flow media

- Drain ports or clean-out manholes for solids-laden systems

- Torsion-free mounting to eliminate off-axis stress

Each assembly undergoes comprehensive QA/QC checks, including dimensional inspection, dye-penetrant testing, hydrostatic testing, and if required, radiographic or ultrasonic examination.

Our team provides:

- Design consultation for new systems and retrofits

- Customized engineering drawings and stress analysis support

- On-site inspection and failure analysis for existing systems

- Installation services

Why Choose VT Top Engineering for Metal Expansion Joints

- Engineering Excellence

Our team brings deep expertise in the design, fabrication, and application of metallic expansion joints. Every unit is precision-engineered to meet exact performance specifications, ensuring safe, reliable operation under extreme thermal, mechanical, and environmental conditions.

- Custom-Built Solutions

We don't offer one-size-fits-all products. Each expansion joint is tailored based on your system layout, movement requirements, and process parameters. From simple axial joints to complex multi-plane assemblies, we deliver fit-for-purpose solutions.

- Superior Materials & Manufacturing

Using only high-grade stainless steels and specialty alloys like Inconel, Incoloy, and Hastelloy, our products are manufactured to exacting standards with robust QA/QC procedures—including pressure testing, NDT, and dimensional inspections.

- Full Lifecycle Support

From pre-design consultation and stress analysis to on-site inspection and failure diagnostics, our technical support covers every stage of your project. We ensure smooth integration and maximum lifecycle value for your system.

- Compliance & Reliability

All our designs conform to global standards such as EJMA and ASME. With proven performance across high-pressure, high-temperature, and vibration-sensitive environments, our joints are trusted by industries including power, petrochemical, marine, and process manufacturing.

- On-Time Delivery, Every Time

We understand the importance of project timelines. Our agile manufacturing processes and experienced logistics ensure timely delivery without compromising on quality.

Partner with VT Top Engineering for engineered expansion joint solutions designed to perform across the toughest mechanical, thermal, and environmental conditions.